Yarn Package Hardness Tester HP-2.5-F

Textile hardness tester (durometer) to determine winding density of closely wound bobbins of synthetic, finished fibers and filaments

Indentor - ball diameter 2.5 mm

The measuring force is according to shore A regulations

Durometer with large working face for bobbins with more than 400 mm diameter

Special Features

Standard Features

Available Models

| Model | Ball Ø | Application | |

| HP-2.5-F | 2.5 mm | for closely wound bobbins of synthetic, finished fibers and filaments with more than 400 mm diameter | |

| alternative | |||

| HP-5-F | 5 mm | for loosely wound bobbins of synthetic fibers and closely wound natural fibers, yarns and threads with more than 400 mm diameter | more |

| HP-10-F | 10 mm | for very loosely wound bobbins of thick yarns with more than 400 mm diameter, such as carpet yarns | more |

| Indentor: | Ball Ø 2.5 mm |

| Area of application: | For closely wound bobbins of synthetic, finished fibers and filaments with more than 400 mm diameter |

| Depth of indentation*: | 0 – 2.5 mm |

| Test pressure**: | Approx. 12.5 N |

| Measuring spring force*: | 0.55 – 8.065 N |

| Display range: | 0 – 100 hardness graduation marks |

| Scale diameter: | 54 mm |

| Working face flat: | 45 mm |

| Weight, net (gross): | Approx. 300 g (500 g) |

| Dimensions: | 50 x 58 x 110 mm (LxWxH) |

Specifications subject to change without notice!

* Meets requirements of Shore A

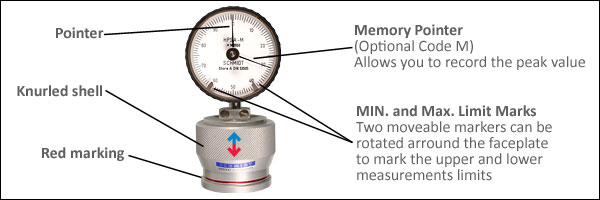

** Spring load of outer ring to create constant pressure when outer ring is pulled to red marking

General:

The principle used to measure textile hardness is based on measuring the resistance force of the penetration of a ball shaped indentor against the spool under a known spring load. The hardness scale covers a range of 0 – 100, were 0 is the smallest and 100 is biggest hardness. The measuring force and the principle relates to the specifications of rubber hardness tester Shore A.

Please note:

There exists no international standard for adjusting and calibration of textile hardness. Therefore we have developed our own test-standard and procedures.

- Code M - Memory pointer

Memory pointer to capture and store value (last or highest reading) during measuring.

Memory pointer to capture and store value (last or highest reading) during measuring.

Order code: HP-2.5-F-M - PSHP - Test Stand

Model PSHP for series measurements

– Spring loaded lever for fast, precise positioning

– Height adjustable 0 – 200 mm

– Stroke lever action 40 mm

– Dimensions 162 x 100 x 320 mm (LxWxH)

– Weight net: approx. 2,3 kg

Various plates are optional available,

ask for more information ! - Calibration Certificate

Calibration certificate with calibration report is optional available.

Calibration certificate with calibration report is optional available.

Yarn package hardness tester HP-2.5-F with carrying case, Certificate of Compliance with the order 2.1 according EN 10204 free of charge, operating instructions in English or German as requested

Yarn package hardness tester HP-2.5-F with carrying case, Certificate of Compliance with the order 2.1 according EN 10204 free of charge, operating instructions in English or German as requested