– plug in probe for one-hand operation

– measuring probe with cable for limited access space

– free strand length 9.99 m

– belt mass up to 9.999 kg/m

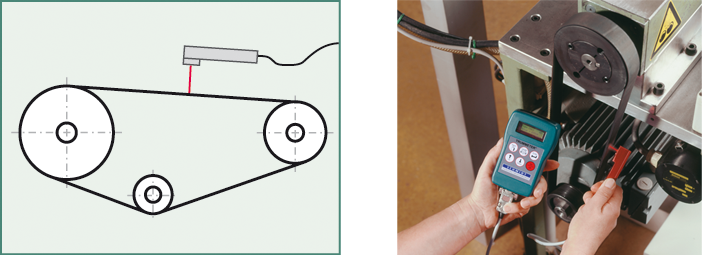

Trummeter for measuring belt tension and for control the strand force of V-belts, tooth belts, power belts or similar. The optimal life time of a belt is depending on the correct belt tension.

The measured value is shown as frequency in Hz or strand force in N.

Non-contact measuring occurs by infrared light

| Model | Measuring Range |

| RTM-400 | max. 10 – 800 Hz |

| Measuring range: | 10 – 800 Hz |

| Digital sampling error: | < 1 % |

| Indicator error: | ±1 Hz |

| Total error: | < 5 % of measuring value |

| Adjustable measuring units: | Hz (Frequency) or N, lbf (Strand force) |

| Measuring distance: | 3 – 20 mm |

| Display: | 2 line LCD, 16 characters per line |

| Languages: | 10 languages (German, English, French, Italian, Spanish, Portuguese, Swedish, Norwegian, Danish, Finnish) |

| Input ranges: | Free strand length: up to 9.99 m Belt mass: up to 9.999 kg/m |

| Temperature ranges: | Operation: +10 °C … 50 °C, Transport: -5 °C … +50 °C |

| Air humidity: | 85 % RH, max. |

| Power supply: | 9 V – Battery |

| Housing: | Plastic (ABS) |

| Dimensions: | 126 x 80 x 37 (LxWxH) |

| Weight net (gross): | Approx. 170 g (660 g) |

Specifications subject to change without notice!

| Ribbed V-belts | PJ = 0.082 PM = 1.100 | PL = 0.320 | kg/m per 10 ribs |

| V-belts | SPZ = 0.074 SPB = 0.195 10 = 0.064 17 = 0.196 22 = 0.324 32 = 0.668 | SPA = 0.123 SPC = 0.377 13 = 0.109 20 = 0.266 25 = 0.420 40 = 0.958 | kg/m per belt |

| Power belts | SPZ = 0.120 SPB = 0.261 3V/9J = 0.120 8V/25J = 0.693 | SPA = 0.166 SPC 0 0.555 5 V/15J = 0.252 | kg/m per rib |

| Polyurethane Toothed belts | T 2.5 = 0.015 T 10 = 0.045 AT 3 0 0.023 AT 10 = 0.063 | T 5 = 0.024 T 20 = 0.084 AT 5 = 0.034 AT 20 = 0.106 | kg/m per 10 mm width |

To measure the belt mass precisely, we recommend that you weigh the drive belt and then recalculate this weight based on a belt length of 1 meter.

The table above contains comparison values for some belts.

The belt tension can be measured only when the drive is stationary. Preferably, the belt tension should always be measured at the center of the longer belt strand between the two drive pulleys. The distance to the belt can be 3 – 20 mm. Depending upon ambient light and surface of belt, the measurement can occur from a distance of max. 60 mm, whereas darker light and better reflection (can be obtained by attaching a reflective tape) admit a larger measuring distance.

The belt tension can be measured only when the drive is stationary. Preferably, the belt tension should always be measured at the center of the longer belt strand between the two drive pulleys. The distance to the belt can be 3 – 20 mm. Depending upon ambient light and surface of belt, the measurement can occur from a distance of max. 60 mm, whereas darker light and better reflection (can be obtained by attaching a reflective tape) admit a larger measuring distance.Measurement:

The belt is tapped in order to make it natural oscillating. This static natural frequency is then measured by the probe with the aid of pulsed light. Care must be taken to ensure the light is sufficiently reflected by the belt. A reflective tape must be fixed if necessary.

General information:

To measure the belt mass precisely, we recommend that you weigh the drive belt and then recalculate this weight based on a belt of 1 meter. The strand force is calculated using the formula:

![]()

| F | = strand force in N |

| m | = linear belt mass in kg/m |

| L | = length of the free belt strand in m |

| f | = natural frequency of the free belt measured in Hz |

Note

Measurement deviations of up to ±10 % for several measurements taken on the same drive belt are as a rule not caused by a measurement error or fault in the unit. In most cases, measurement deviations are due to the mechanical tolerances of the drive systems.

Attention!

Newton- or poundforce-calculations have a square factor higher error result!

Set point:

The set point for belt tension is specified as natural frequency in Hz or as strand force in N.

It is depending to the characteristics of the drive. Alternative the set point can be calculated with the formula:

![]()

| P | = motor power in kW |

| z | = number of belts |

| v | = speed of belt = D x n/19100 |

| D | = effective diameter of the small pulley in mm |

| n | = revolution of the small pulley (Upm) |

| m x v² | = centrifugal force (relevant for revolutions > 800 Upm) |

| m | = weight of belt in kg/m according the table (for a belt) |

for measurements in hard to reach places, Weight 0.1 kg

Order number: 45005H

for measurements in hard to reach places, Weight 0.12 kg

Order number: 45006H

Belt tension meter RTM-400 with carrying case, 2 measuring probes, 1 battery, manufacturer`s calibration report and operating instruction in German and English

Belt tension meter RTM-400 with carrying case, 2 measuring probes, 1 battery, manufacturer`s calibration report and operating instruction in German and English