– V-grooved (for material with max. 4 mm Ø)

– U-grooved (for material with 3 up to 10 mm Ø)

– tape grooved (for material with max. width of 10 mm)

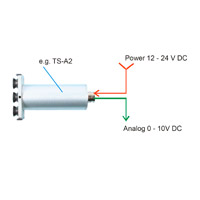

– analog: 0 – 1 V (standard), 0 – 10 V (optional)

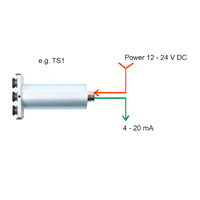

– current: 4 – 20 mA (optional)

– analog DMS: mV/V (optional)

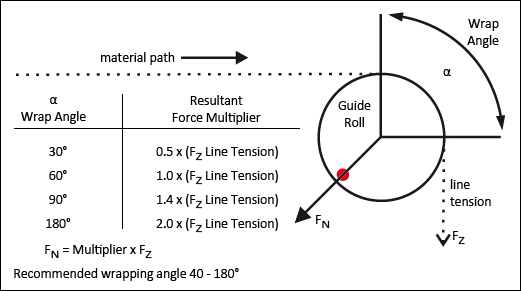

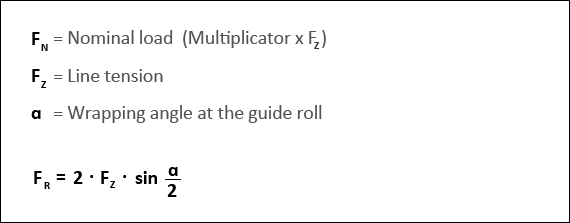

When selecting the nominal measurement force it is necessary to take into account the weight of the guide roll and raise the nominal load respectively, particularly when working with small nominal forces.

When selecting the nominal measurement force it is necessary to take into account the weight of the guide roll and raise the nominal load respectively, particularly when working with small nominal forces.