Shore Durometer HPSA

Durometer according to Shore for determining the indentation hardness of soft rubber, elastomers, natural rubber, polyester, soft PVC, leather, etc.

Shore A hardness tester according DIN 53505, ISO 48-4, ISO 868 and ASTM D 2240

Durometer with large seating for accurate measuring

Special Features

Standard Features

Available Models

| Model | Shore | Application | |

| HPSA | Shore A | soft rubber, elastomers, natural rubber, soft PVC, leather, etc. | |

| alternative | |||

| HPSA-R-M | Shore A | rubber coated rollers, rollers, and cots | more |

| HPSB | Shore B | for harder material than Shore A | more |

| HPSC | Shore C | medium hard rubber, elastomers and plastic | more |

| HPSDO | Shore DO | plastic and medium hard to hard rubber materials | more |

| HPSD | Shore D | plastic and medium hard to hard rubber materials | more |

| HPSO | Shore O | soft elastomers, soft elastic materials, medium fast textiles | more |

| HPSAO | Shore AO | foams, steering wheels and inner linings of motor vehicles | more |

Indentor

| Cone | Tapered pin | U-grooved | Ball |

Shore C | Shore D |  Shore O Shore OShore DO |

| Indentor: | Cone 35°, Ø 1.25 mm |

| Depth of indentation: | 0 – 2.5 mm |

| Typical applications: | Soft rubber, elastomers, natural rubber, soft PVC, leather, etc. |

| Accuracy: | ± 1 hardness unit |

| Application range: | 10 – 90 Shore A |

| Standard: | DIN 53505, ISO 48-4, ISO 868, ASTM D 2240 |

| Measuring spring force: | 0.55 – 8.065 N |

| Test pressure*: | Approx. 12.5 N |

| Display range: | 0 – 100 Shore A units |

| Scale diameter: | 54 mm |

| Working face: | 18 mm Ø |

| Base plate: | 45 mm Ø |

| Weight, net (gross): | Approx. 300 g (500 g) |

| Dimensions: | 50 x 58 x 114 mm (LxWxH) |

Specifications subject to change without notice!

* Spring load of outer ring to create constant pressure

General:

The principle used to measure shore hardness is based on measuring the resistance force of the penetration of a pin into the test material under a known spring load. The amount of penetration is converted to hardness reading on a scale with 100 shore units.

As the depth of indentation is max. 2.5 mm the test material has to have a minimum thickness of 6 mm. If thickness is less stack some samples till you reach the required thickness.

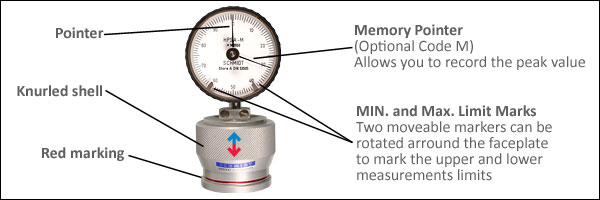

- Code M - Memory pointer

Memory pointer to capture and store value (last or highest reading) during measuring.

Memory pointer to capture and store value (last or highest reading) during measuring.

Order code: HPSA-M - PSHP - Test Stand

Model PSHP for series measurements

– Spring loaded lever for fast, precise positioning

– Height adjustable 0 – 200 mm

– Stroke lever action 40 mm

– Dimensions 162 x 100 x 320 mm (LxBxH)

– Weight net: approx. 2,3 kg

Various plates are optional available,

ask for more information ! - HP-P20-100 - Control Rings for 20, 40, 60 and 80 Shore

To determine the displacement at 20, 40, 60 and 80 Shore.

To determine the displacement at 20, 40, 60 and 80 Shore.

Includes a base disk as basis for the control rings and an inspection certificate.

Order number: HP-P20-100 - Calibration Certificate

Calibration certificate with calibration report is optional available.

Calibration certificate with calibration report is optional available.

Durometer HPSA with carrying case, Certificate of Compliance with the order 2.1 according EN 10204 free of charge, operating instructions in English or German as requested

Durometer HPSA with carrying case, Certificate of Compliance with the order 2.1 according EN 10204 free of charge, operating instructions in English or German as requested